April 20, 2021 – Flyability has introduced a groundbreaking software called Inspector 3.0, designed to help inspectors quickly and accurately identify where defects are located during inspections.

Flyability, a pioneer in remote internal inspection solutions, is proud to announce the release of Inspector 3.0, a powerful tool that enables users to precisely locate defects found during inspections using the Elios 2 drone. After a successful beta period with over 150 participants, the software is now available for all Elios 2 users worldwide.

"Inspector 3.0 marks a significant step forward in our mission to eliminate the need for humans to enter dangerous or confined spaces," said Patrick Thévoz, CEO of Flyability. "Being able to pinpoint exactly where an issue is within an asset improves efficiency and delivers more value to our clients."

During manual inspections, technicians can easily spot issues because they're physically present at the location. However, when using RVI tools like the Elios 2, it's much harder to determine where a defect is located due to the absence of GPS or indoor positioning systems.

Previously, inspectors had to rely on a mix of barometric data, blueprints, maps, and video references to estimate the location of a defect. This process was time-consuming and often inaccurate.

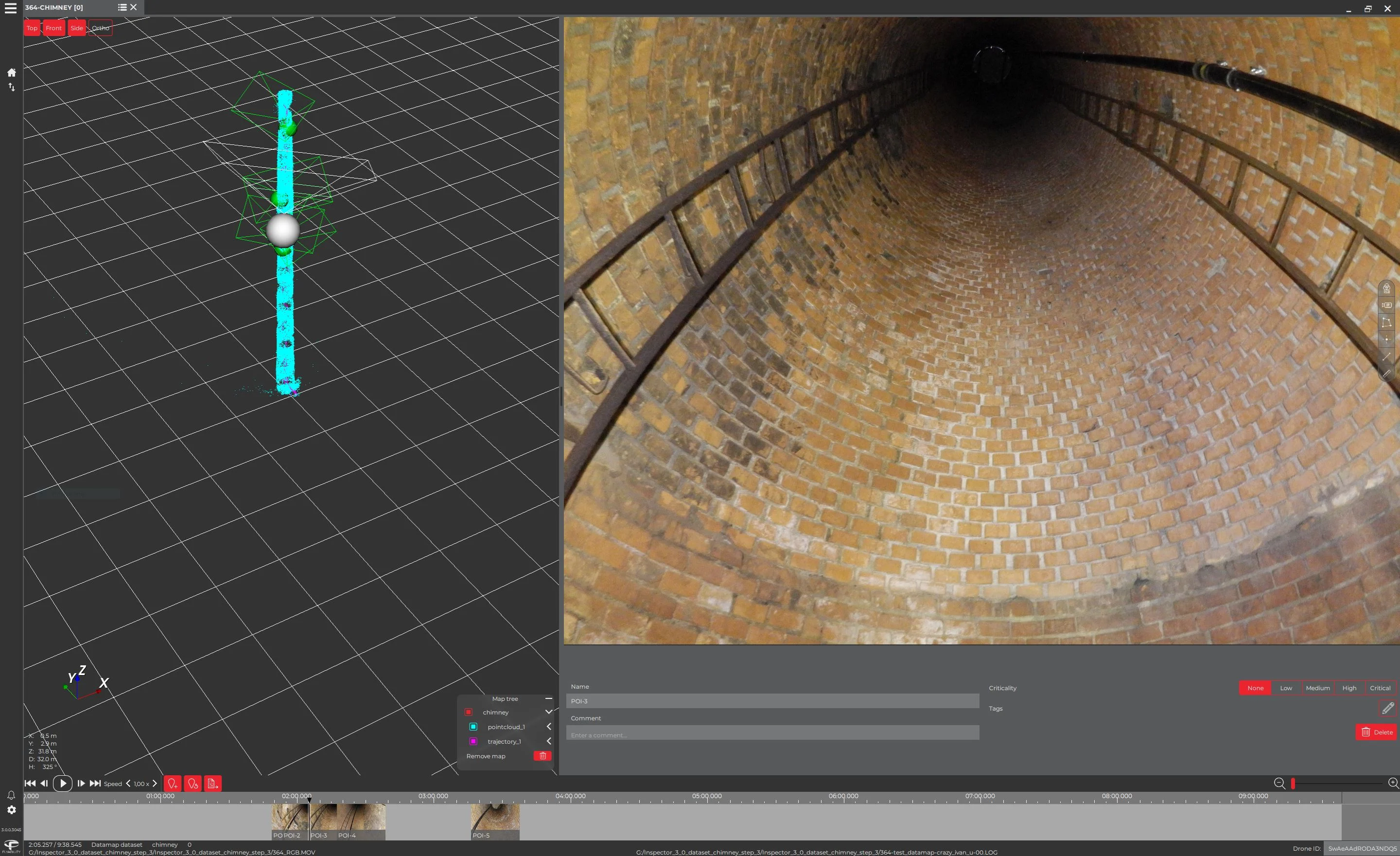

With Inspector 3.0, inspectors can now generate a sparse point cloud that visually represents where defects are located within the asset—using only the data collected by the Elios 2. Unlike other methods such as LiDAR or photogrammetry, this approach is cost-effective and fast.

"We often know there’s damage inside an asset, but not exactly where," said Simon Kumm, Confined Space Inspections Expert at InspecDrone GmbH. "Inspector 3.0 solves this problem effectively."

Accurate location data is essential in maintenance operations. For example, if a pipe in a wastewater system needs repair, digging in the wrong place could lead to wasted time and resources. With precise localization, teams can plan more effectively and avoid costly mistakes.

It also helps coordinate different teams involved in a project. Scaffolders can prepare the site properly, and repair crews can visualize all the defects and understand their exact locations before entering the space.

"The localization feature in Inspector 3.0 is exactly what we've been waiting for," said Thibault Chatillon, Innovation and Development Manager at Setec. "Our customers have asked for this for a long time. Now, I can show them exactly where the issue is."

Learn more about Inspector 3.0.

---

About Flyability

Flyability is a Swiss company dedicated to creating innovative solutions for inspecting and exploring inaccessible, confined, and indoor spaces. By enabling drones to operate safely indoors, Flyability helps industrial companies and inspection professionals reduce downtime, lower costs, and improve worker safety. With hundreds of customers across 50+ countries in sectors like Power Generation, Oil & Gas, Chemicals, Maritime, Infrastructures, Utilities, and Public Safety, Flyability has become a leader in the commercial indoor drone market.

For more information, visit www.flyability.com or follow us on @fly_ability.

Contact: info@flyability.com, +41 21 311 55 00

Ground Screw,Earth Screw Post Ground Screw,Solar Mounting Earth Screw Pile,Carbon Steel Solar Ground Screw

Taian Longye Import And Export Trade Co.,ltd , https://www.drillingrigfactory.com