Unlocking the Potential of Groundwater Replenishment Systems in Southern California

Water Infrastructure in Orange County

Orange County, located in southern California, is home to over 3 million people and faces growing water demands due to population growth. To address this challenge, the Orange County Water District (OCWD) has developed an innovative solution: the Groundwater Replenishment System (GWRS). This system not only provides a reliable source of water but also helps reduce dependence on imported water, making it a key player in regional sustainability efforts.

Despite receiving less than one-third of California’s total rainfall, southern California holds two-thirds of the state's population. This imbalance creates significant pressure on local water resources. While OCWD does import some water, the process is expensive and energy-intensive. Additionally, other regions and countries share similar water sources, further complicating availability as precipitation levels decline.

The primary water source for Orange County is a large groundwater basin that supplies about 300,000 acre-feet annually. However, since the 1940s, natural recharge has struggled to keep up with demand, leading to concerns about seawater intrusion. In response, OCWD launched its groundwater replenishment program, which now plays a critical role in protecting the basin and ensuring a sustainable supply of clean water.

Water Infrastructure: The Five-Step Process

- Pre-purification: Before entering the GWRS, wastewater from the Orange County Sanitation District undergoes extensive treatment. This includes screening, biological processes, and chemical control to remove contaminants and ensure high-quality water before further purification.

- Microfiltration: Water is passed through tiny pores in hollow fiber membranes, effectively removing solids, bacteria, and even some viruses.

- Reverse Osmosis: High-pressure filtration removes dissolved salts, chemicals, and pharmaceuticals, resulting in highly purified water that needs mineral addition for stability.

- Ultraviolet Light with Hydrogen Peroxide Treatment: This final disinfection step uses UV light and hydrogen peroxide to neutralize any remaining impurities, ensuring safe drinking water.

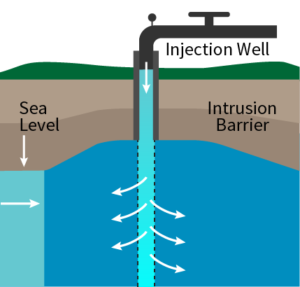

- Water Delivery: A portion of the treated water is injected into coastal wells to prevent seawater intrusion, while the rest is released into local lakes to naturally filter back into the groundwater basin.

Since its launch in 2008, the GWRS has become the largest advanced water recycling facility in the world, producing up to 100 million gallons of clean water daily. It stands as a model for sustainable water management, proving that innovation can help communities thrive even in the face of environmental challenges.

Dispersing Machine,Dispersion Kneader,Dispersion Kneader Machine,High Speed Dispersion Machine

wuxi top mixer equipment co.,ltd , https://www.wxtpmixer.com