What Does a Drone Cage Do? Use Cases, Types & Indoor Inspections

There are three different types of drone cages on the market—read this article to learn about each one.

Drone cages serve a dual purpose: they protect people from potential harm caused by a drone’s propellers and also safeguard the drone itself from damage in case of a collision. These cages aren’t just about survival—they can actually allow a drone to collide and keep flying.

But not all drone cages are created equal. Some are designed as add-ons for commercial drones, while others are built specifically for drones meant to operate in tight or confined spaces where collisions are more common.

In this article, we’ll explore the various scenarios that require a drone cage, examine the three main types available, and dive deeper into their most popular applications.

Understanding Drone Cages: Attachments vs. Enclosures

Before we go further, it's important to clarify that the term “drone cage†can refer to two different things. Sometimes it refers to an enclosure used at events like trade shows or drone races to protect people from potential drone accidents. These enclosures are often made of netting or wire mesh, like the ones seen in public demonstrations.

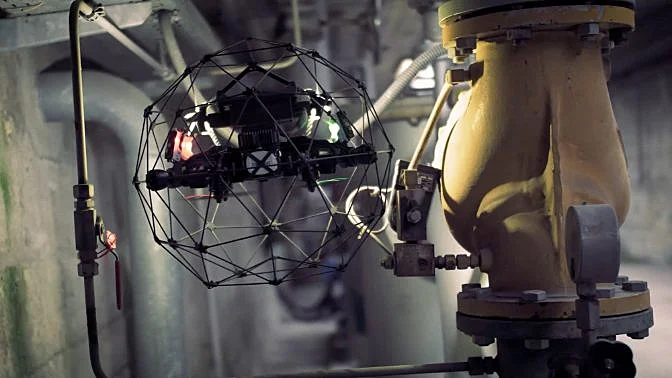

However, when we talk about “drone cages†in this article, we’re referring to those that are attached directly to the drone, such as the ones found on Flyability’s Elios 3:

The Origin of the Drone Cage

Drone cages have opened up a wide range of new applications, especially for flying indoors. But how did this idea come about?

It started after the 2011 Fukushima nuclear disaster. The need for remote visual data collection without risking human lives led to the development of collision-tolerant drones. This inspired the creation of the Elios 1, Elios 2, and Elios 3—drones with built-in cages designed for safe operation in dangerous environments.

The Elios 2 drone cage in action

The Elios 2 drone cage in action

Why Use a Drone in Confined Spaces?

Safety is the primary reason to use a drone instead of a person in confined areas. For example, during the Fukushima disaster, it was too dangerous for humans to enter the reactor, but drones could collect critical visual data.

Similarly, in industries like mining, construction, and utilities, drones equipped with cages help inspectors gather visual data without putting workers at risk. They also save companies money by reducing the need for scaffolding and minimizing downtime.

Where Are Drone Cages Used?

Drone cages are used wherever there’s a risk of collision and where drones and people share space. They’re ideal for disaster scenarios, industrial inspections, and everyday operations in challenging environments.

Some common applications include:

- Inside nuclear power plants for routine inspections

- Inside boilers or pressure vessels in the oil and gas industry

- Inside mines to inspect excavations

- Inside burned-out buildings for safety assessments

- Inside sewer systems to identify damage

- Inside water parks to monitor infrastructure

The Three Types of Drone Cages

Currently, there are three main types of drone cages on the market:

- Add-on cages

- Decoupled cages

- Fixed cages

1. Add-On Drone Cages

Add-on cages are designed to be attached to commercial drones. While they improve safety, they are not always ideal for industrial inspections. They may reduce flight time, lack obstacle sensing, and don’t provide the same level of collision tolerance as specialized drones.

2. Decoupled Drone Cages

Flyability’s Elios 1 uses a decoupled design, allowing the drone to remain stable even after collisions. This makes it ideal for tight spaces and complex maneuvers.

3. Fixed Drone Cages

Fixed cages, like those on the Elios 2 and Elios 3, are built into the drone’s design. They offer superior stability, collision resistance, and advanced features like GPS-free stabilization and live HD streaming.

Glass Vacuum Lifter Application

The Vacuum Glass Lifter is a specialized tool designed for the installation of Glass Curtain Walls and Glass windows. It is capable of lifting heavy glass windows weighing between 300kg to 750kg, making it an invaluable aid in the installation of these large glass components. As the demand for larger and heavier glass curtain walls in various majestic buildings increases, our company has developed a Hydraulic Powered Rotation and Tilting Glass Vacuum Lifter that can handle glass units with a maximum load of 15,000kg.

The Vacuum Glass Lifter has become a crucial tool for the installation of glass components in numerous high-profile buildings around the world. Many renowned construction companies, such as China State Construction Engineering Corporation, Beijing JangHo Curtain Wall Company, CNYD, YASHA, FangDa, and others, have continuously cooperated with us. Together, we have successfully completed numerous high-profile projects. The quality and consistent performance of our products have been recognized and praised by both domestic and international customers.

The Vacuum Glass Lifter offers a range of features that make it an exceptional tool for the installation of glass components. It is designed to be durable, reliable, and efficient, ensuring a smooth installation process. The hydraulically powered rotation and tilting mechanism allows for precise control and maneuverability, making it easy to position and align the glass units accurately. The lifter's vacuum pads adhere securely to the glass surface, providing a stable and secure lifting solution.

The use of the Vacuum Glass Lifter has numerous benefits in the installation of glass components. It significantly reduces the physical effort required, as it lifts the glass units effortlessly, even in their most cumbersome and heavy forms. It also ensures the safety of the installation crew as it eliminates the need for manual handling of the glass units, reducing the risk of accidents and injuries.

In conclusion, the Vacuum Glass Lifter is a highly versatile and efficient tool for the installation of glass components in various high-profile building projects. Its durability, reliability, and precision make it an essential tool for glass curtain wall and glass window installation. It has been continuously praised by our long-term cooperating construction companies and has successfully completed numerous high-profile projects worldwide. The Vacuum Glass Lifter is a testament to our commitment to providing innovative and reliable lifting solutions that meet the challenges of modern construction.

Glass Vacuum Lifter Application ,Glazing Suction Lifters,Heavy Duty Glass Lifter,Glass Vacuum Suction Cups Lifters,Remote Control Glass Lifter

Guangdong Cowest Machinery Equipment Co.,ltd. , https://www.cowestmac.com