Mining Drones: Elios 2 Enables Photogrammetric Modeling

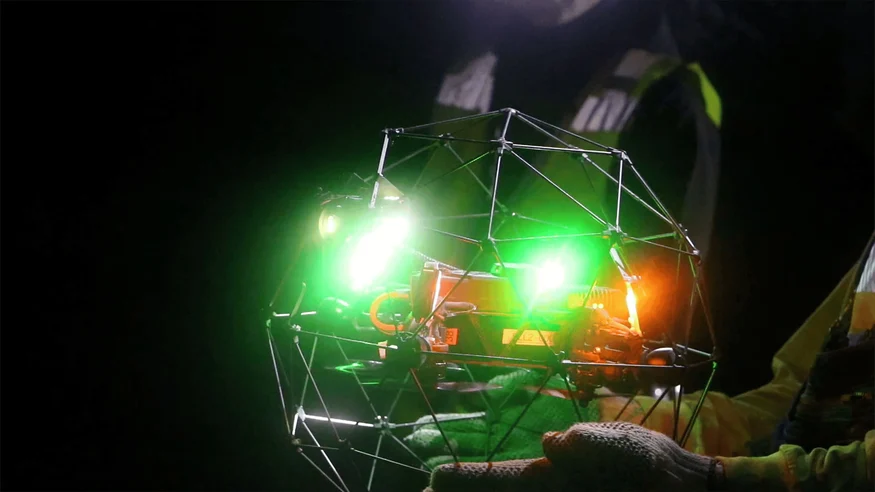

Drones have become a staple in the mining industry for mapping open-pit mines, but exploring underground areas has always been a challenge. Enter Elios 2—a cutting-edge drone designed specifically for confined spaces and GPS-denied environments. With its advanced photogrammetric capabilities, Elios 2 brings clarity to the darkest corners of the earth, making it an essential tool for modern mining operations.

Key Benefits at a Glance

|

Safety By capturing high-resolution visual data from dangerous areas, Elios 2 enables safety assessments that were previously impossible. This reduces the risk of exposing workers to hazardous underground conditions. |

High-Quality Data The drone delivers 4K video and sharp images, offering valuable insights for engineering, surveying, and safety teams. This data plays a crucial role in optimizing stope development and maintenance. |

Ease of Use Its stable flight and durable cage design allow for thorough inspections without the fear of crashes. Even inexperienced users can operate the drone effectively. |

Introduction

For three days, Flyability’s Elios 2 was tested at Barrick Gold Corporation’s Golden Sunlight Mine in Whitehall, Montana. The drone, designed for confined space inspections, proved its worth in challenging underground conditions. Matt Mackinnon, founder of UAS Inc., played a key role in guiding the development of the Elios 2 and helped demonstrate its capabilities during the test.

“The Elios 2 checks nearly every box for what we need to conduct safe and effective underground inspections,†said Matt. “From its stability to its image quality, it's a game-changer.â€

Using data from the Elios 2, the team created a detailed 3D photogrammetric model of a stope, helping mine personnel assess its condition, identify hazards, and plan future operations more effectively.

Customer Needs

After blasting, large rocks can hang in a stope, posing serious risks to equipment and personnel. Traditional methods like lowering cameras or using poles offer limited access and often fail to provide accurate data. This lack of visibility leads to potential damage, safety issues, and lost ore.

Barrick wanted to gather enough visual data to create a detailed 3D map of a stope, ensuring safer operations and better decision-making. The ability to detect fractures, loose material, and other geological features is crucial for preventing collapses and managing resources efficiently.

[Related read: What is a LiDAR drone?]

Solution

Ryan Turner, a geotechnical engineer with Barrick, led the inspection missions alongside Matt Mackinnon and the Flyability team. The Elios 2 performed flawlessly in both large and tight spaces, capturing high-quality data even in harsh conditions.

“It’s safe to interact with, and the cage protects it from collisions,†said Ryan. “We could capture footage that was much more accurate than anything we’ve done before.â€

Results

The Elios 2 successfully navigated large spaces and tight shafts, collecting data that was far more comprehensive than previous methods. Its lighting system illuminated dark areas, and the protective cage prevented damage during collisions.

The drone revealed how much material had mixed into the ore and provided clear images of geological structures. This allowed engineers to assess stability and identify risks accurately.

“The imagery looked really good,†said Ryan. “We could see where the structures were releasing material.â€

Even first-time users found the Elios 2 easy to fly. Over three days, five drones were used without any loss, highlighting its reliability and user-friendly design.

Photogrammetric Mapping—In Testing and Development

Over four flights, the Elios 2 collected enough data to create a 3D photogrammetric model of a stope using Pix4D Mapper. These models provide critical insights into the condition of excavation sites and help track changes over time.

Geotechnical engineers can use these models to compare before-and-after scenarios, analyze rock movement, and guide future operations. Clicking on specific points in the model allows for close-up views of geological features, improving accuracy and decision-making.

Conclusion

The Elios 2 has transformed the way mining companies like Barrick Gold approach underground inspections. It provides safe, accurate, and reliable data that enhances operational efficiency and safety. By enabling the creation of 3D photogrammetric models, the Elios 2 helps reduce risks, save costs, and improve decision-making across the mining process.

This article is part of a series on photogrammetry:

- Why use photogrammetry to build 3D models of indoor spaces?

- Mining Drones: Elios 2 Creates Photogrammetric Models

- Building 3D Models with Elios 2: How to Acquire Appropriate Data for Photogrammetry

- Building 3D Models with Elios 2: Processing Data with Photogrammetry Software

- Elios 2 Tested for Indoor Stockpile Volumetry, Produces 3D Maps Accurate to Within 1 Centimeter

Sewing Machine Spare Parts,Sewing Machine Spares,Stitching Machine Spare Parts,Tailoring Machine Spare Parts

Ningbo Dingming Machinery Manufacturing Co.,Ltd , https://www.dingmingmachine.com