AMADA, MURATA, TRUMF, STRIPPET, LVD, FIN POWER, JIN FANGYUAN, YANGLI, JIEMAI IN JINAN, TAILIFT and so on punch machines.

We have customers over world, such as UK, USA, Italy, Romania, Russia, Ukraine, Brazil, Colombia, Peru, Venezuela, Ecuador, Paraguay, Chile, India, Pakistan, Singapore, Vietnam, Iran and so on, More than 50 countries.

| Punch Tool | |

| Model Number | Punch Die |

| Material | HSS M-2, SKH-9, SKD11,ASP23,ASP30 etc |

| Hardness | determined by material |

| Size | According to customer requirement |

| Thickness | According to customer requirement |

| Edm precision | 0.002mm |

| Quality Control | Computer quality control system |

| Certificate | ISO9001:2008 and ISO14000,CE |

| Deliver time | 3-7 days |

| Package | Wooden case |

| Supply for | Turret Punch Machine |

| Customer | More than 50 countries |

| Service Center | More than 20 countries |

| Sample | Can supply |

| Service Type | OEM/ODM |

| Surface Treatment | Powder coating, painting, galvanizing, electroplating, anodising, chromeplating, brushing, polishing,silk-screen,printing |

| Producing Process | Shearing,laser cutting, punching, deburring,bending, pressing, welding, riveting,grinding,surface treatment, assembling |

We can supply the Punching tool of different series, suitable for:

AMADA, MURATA, TRUMF, STRIPPET, LVD, FIN POWER, JIN FANGYUAN, YANGLI, JIEMAI IN JINAN, TAILIFT and so on punch machines.

We have customers over world, such as UK, USA, Italy, Romania, Russia, Ukraine, Brazil, Colombia, Peru, Venezuela, Ecuador, Paraguay, Chile, India, Pakistan, Singapore, Vietnam, Iran and so on, more than 50 countries.

| Punch Tool | |

| Model Number | Punch Die |

| Material | HSS M-2, SKH-9, SKD11,ASP23,ASP30 etc |

| Hardness | determined by material |

| Size | According to customer requirement |

| Thickness | According to customer requirement |

| Edm precision | 0.002mm |

| Quality Control | Computer quality control system |

| Certificate | ISO9001:2008 and ISO14000,CE |

| Deliver time | 3-7 days |

| Package | Wooden case |

| Supply for | Turret Punch Machine |

| Customer | More than 50 countries |

| Service Center | More than 20 countries |

| Sample | Can supply |

| Service Type | OEM/ODM |

| Surface Treatment | Powder coating, painting, galvanizing, electroplating, anodising, chromeplating, brushing, polishing,silk-screen,printing |

| Producing Process | Shearing,laser cutting, punching, deburring,bending, pressing, welding, riveting,grinding,surface treatment, assembling |

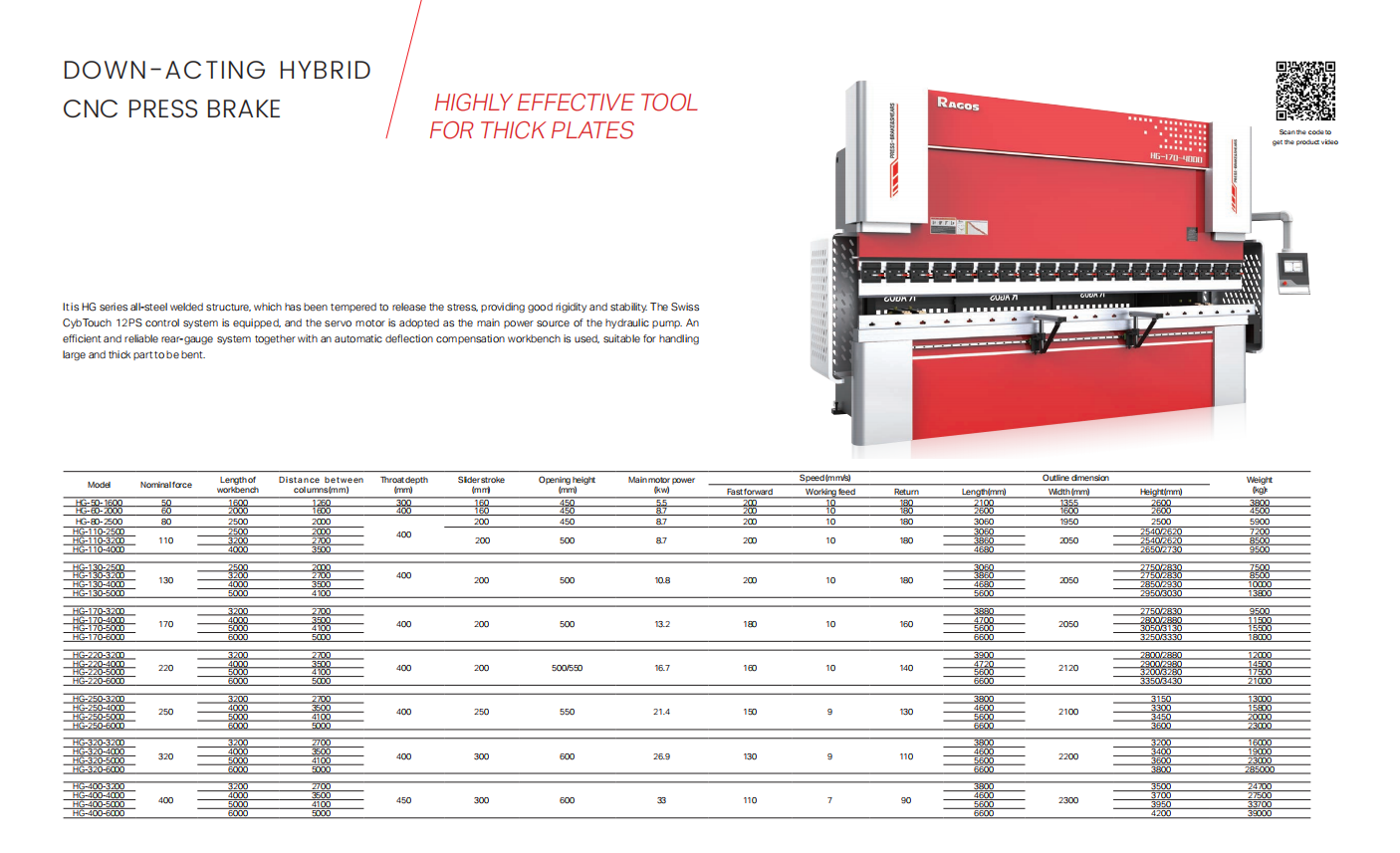

Dual servo hybrid CNC Press Brake

Features:

Introduction:

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Features And Function

Fast - 10% performance increase by reducing cycle time

High efficiency - 50% increase in energy efficiency (compared to traditional systems)

Precise - positioning accuracy reaches 0.005mm

Reliable - minimal risk of leakage

Low Noise - Noise reduction in all operating modes

compact - creating new spaces on the midplane

Compatible - easy integration into CNC

Optimization - less installation and service fees

Environmental protection - the amount of hydraulic oil is greatly reduced

Down-acting press brake,sheet metal panel benders,cnc panel bender,Automatic Panel Bender,Sheet Metal Bending Center,ragos

FOSHAN RAGOS NC EQUIPMENT CO.,LTD. , https://www.ragosnc.com