Â

Â

LED technology has completely transformed the lighting industry. Compared to traditional options like incandescent and fluorescent bulbs, LEDs offer greater energy efficiency, improved light quality, and a longer lifespan—features that have made them a top choice across many industries. According to the U.S. Department of Energy, LED lighting accounted for 48% of installed lighting units in 2020, up from just 8% in 2015 and 1% in 2010.

Â

As LED adoption continues to grow, so does the competition among manufacturers to produce the brightest and most efficient lighting fixtures. In this race, one key metric often used is “luminous efficacy,†which measures how effectively a light source converts electrical power into visible light. While it's an important factor when evaluating performance, it's also become a point of confusion and even misrepresentation in some cases.

Â

One common issue is that some manufacturers test only the bare LED chip rather than the full fixture—including lenses and other optical components. This can lead to inflated efficacy numbers that don’t reflect real-world performance. As a result, it becomes challenging for buyers to compare products fairly or understand what they're actually getting.

Â

In this article, we'll explore what luminous efficacy really means, why it matters for solar lighting, how some manufacturers may exaggerate their claims, and what you can do to ensure you’re choosing reliable, high-performance LED systems.

Â

What is Luminous Efficacy?

Â

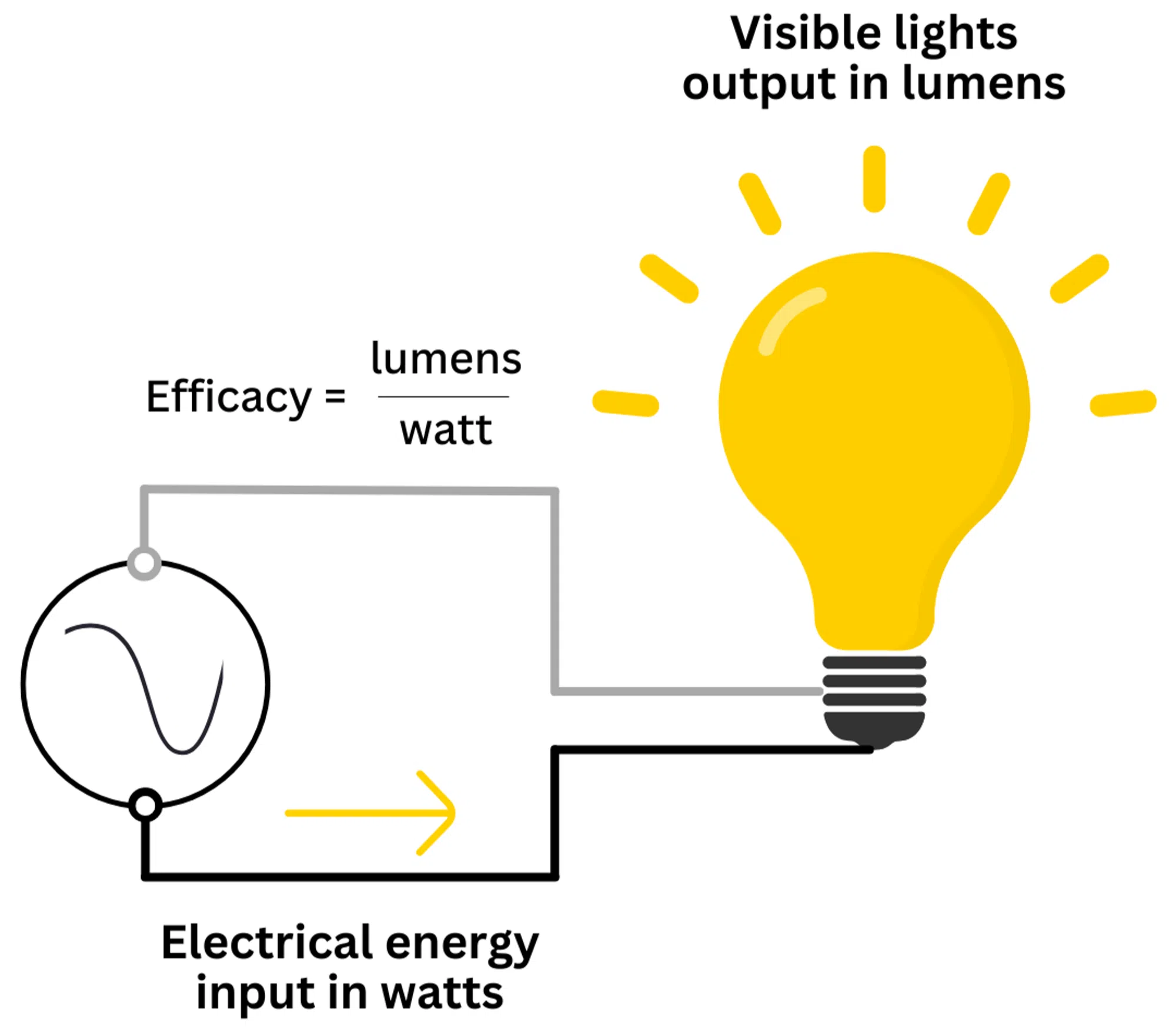

The Illuminating Engineering Society (IES) defines luminous efficacy as the total amount of visible light (in lumens) produced by a light source divided by the power (in watts) it consumes. It’s measured in lumens per watt (Lm/W). For example, a fixture that emits 1500 lumens while using 20 watts has an efficacy of 75 Lm/W. If another fixture produces 2500 lumens with the same 20 watts, its efficacy would be 125 Lm/W—significantly higher.

Â

While efficacy is a useful way to compare the efficiency of different light sources, it's not the same as "efficiency." Efficacy focuses on the ratio of light output to power input, whereas efficiency refers to how much of the emitted light is actually delivered to the intended area. Understanding this distinction helps avoid confusion when evaluating lighting options.

Â

Â

For solar lighting applications, where energy comes from the sun, efficacy is especially important. A higher efficacy means more light is generated with less power, which reduces the size and cost of solar panels and batteries. This makes solar lighting more affordable and practical, especially in remote or high-latitude areas where sunlight is limited.

Â

Why Does Efficacy Matter for Solar Lighting?

Â

Solar lighting systems rely entirely on stored energy, so every watt counts. A high-efficacy LED can provide more light while using less power, which extends the system’s runtime and reduces the need for larger, more expensive components. This makes solar lighting more sustainable and cost-effective over time.

Â

Even though solar energy is free, it’s not always abundant. In low-light conditions or during long winter nights, maximizing the efficiency of your lighting system becomes crucial. That’s why understanding and verifying the true efficacy of a product is so important.

Â

How Do Manufacturers Misrepresent Efficacy?

Â

Some manufacturers take advantage of unclear testing standards by measuring the raw output of the LED chip without including secondary optics like lenses. This can artificially inflate efficacy numbers, making their products seem more efficient than they actually are in real-world conditions.

Â

Lenses play a vital role in directing and distributing light evenly. By excluding them from testing, manufacturers may show impressive results, but these numbers won’t match what you get once the fixture is installed. This lack of transparency can make it difficult for customers to choose the right product.

Â

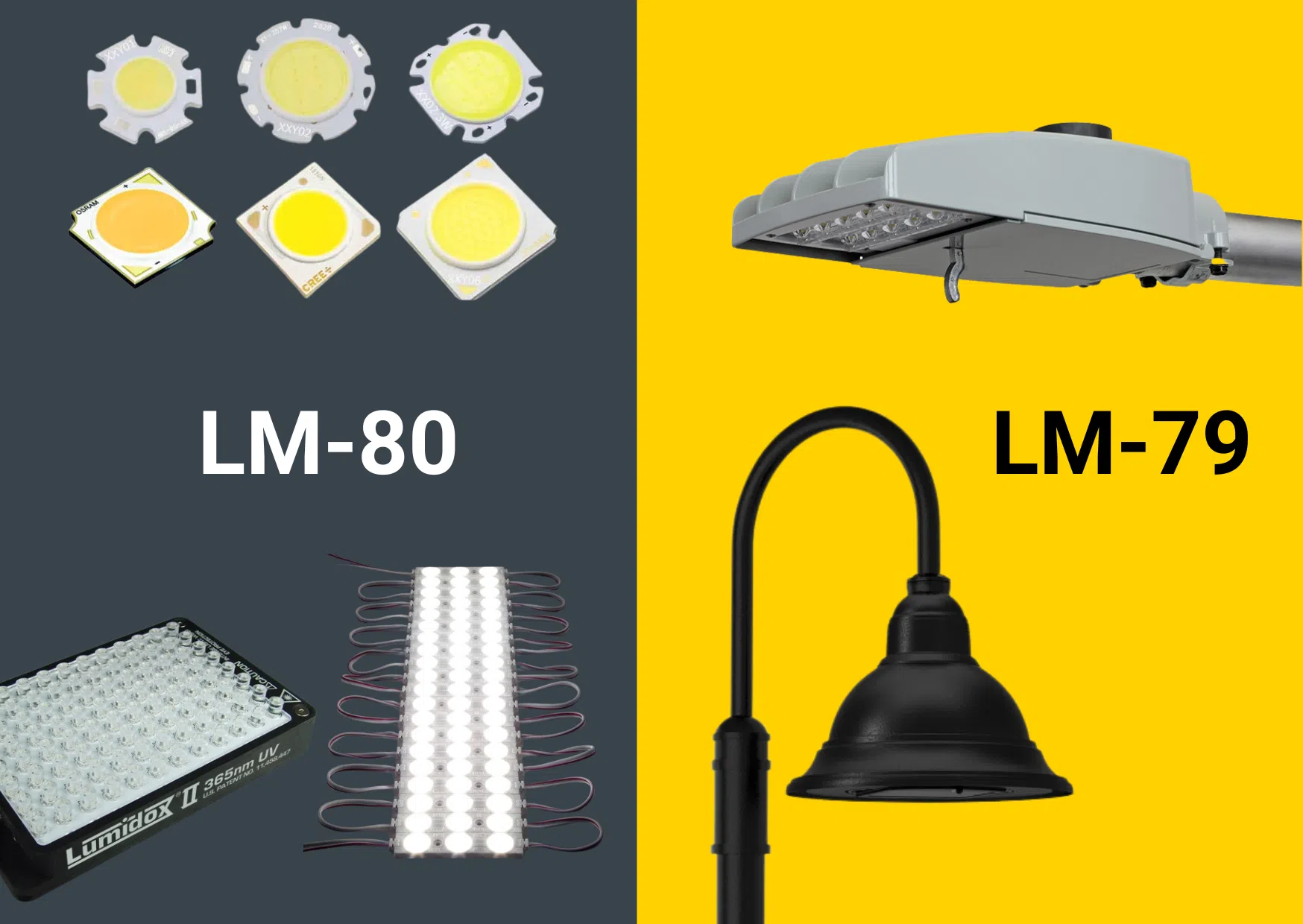

One way to identify trustworthy products is to look for LM-79 testing, which is an industry-standard method for measuring the performance of complete lighting fixtures. LM-79 tests include efficacy, lumen output, and other critical metrics, ensuring accurate and comparable data between different brands and models.

Â

The Importance of LM-79 Testing

Â

LM-79 is an IES-approved standard that provides reliable data on the optical and electrical performance of solid-state lighting products. Unlike other tests like LM-80—which focus on lumen depreciation—LM-79 evaluates the full system, including drivers and lenses. This makes it the most accurate way to assess real-world performance.

Â

To check if a product has undergone LM-79 testing, look for technical documentation or contact the manufacturer directly. Reputable companies will typically provide this information on their websites or upon request.

Â

Â

Other Red Flags to Watch For

Â

Beyond LM-79, there are several signs that a product might be exaggerating its efficacy. For example, if a manufacturer reports an unusually high or low efficacy compared to industry standards, it could be a red flag. Also, if a product claims the same efficacy at both low and high power levels, that’s suspicious—efficacy should decrease as power increases.

Â

When in doubt, ask the manufacturer for independent test reports, photometric data, and details about how they measure their products. These questions can help you make a more informed decision and avoid misleading claims.

Â

Making Informed Purchase Decisions

Â

Understanding luminous efficacy is essential when choosing the right lighting solution. However, not all manufacturers follow the same testing methods or use the same terminology. That’s why standardized tests like LM-79 are so valuable—they allow for fair comparisons and help ensure you’re getting a product that delivers on its promises.

Â

If you can’t find clear information on a manufacturer’s website, don’t hesitate to ask questions. Here are a few key ones to consider:

- Can you provide independent testing results for your efficacy claims?

- How do you measure lumens in your products?

- What is the total fixture efficacy, including drivers and lenses?

- Can you share photometric reports for your fixtures?

- Are your efficacy claims based on initial or maintained lumens?

- Do you have references or case studies from similar projects?

Â

Have a question about efficacy or anything else? Our team of solar lighting experts is here to help. Reach out anytime—we’d love to hear from you.

Â

EVA shrink films are designed for products that require high shrinkage but medium barrier properties,such as frozen meat.Made of EVA/PE material,it has the characteristics of high water vapor barrier,excellent transparency and gloss,high puncture resistance and so on.We can custom any sizes you need for large quantity,and also offer standard sizes for most customers.

Here are the standard widths:

165mm,180mm,190mm,205mm,225mm,250mm,275mm,300mm,325mm,350mm,375mm,400mm,425mm,450mm,475mm,500mm,and the length can be any size.

We also provide printing service with flex Packaging Machine,the machine can print 20 colors at most. Below are packaging operations:

1. Set appropriate temperature on the vacuum machine and hot water tunnel;

2. Place opening of EVA Shrink Film over the sealing bar. Make sure the product is not too hot (with vapor) and with minimal contamination to ensure longer shelf life. Examine that there are no wrinkles over the sealing area to avoid breakage;

3. Make sure the product has not been pressed at the bottom of the EVA Shrink film, and the area of the seal is completely clean;

4. Leave about 5cm space between product and vacuum seal. This is to improve vacuum effect, and also to allow some room for product to expand after freezing (for frozen product);

5. Place vacuum packed product in water for 1-2 seconds.

Barrier shrink EVA Shrink film is a flexible packaging solution made of plastic shrink EVA Shrink film,which shrinks around the product after heating,just like the second layer of skin of the product.The barrier shrink EVA Shrink film protects the product throughout the distribution process.If the packaging EVA Shrink film is accidentally damaged,it can significantly reduce the impact on the meat and minimize the loss.

These shrink EVA Shrink films have barrier properties to prevent ambient gases, moisture, aroma and other factors.

With excellent sealing performance, excellent puncture resistance, transparency and excellent adhesion, barrier shrink EVA Shrink film has attracted extensive attention among end users.

Shelf life is one of the most critical factors when end users use packaged food.Barrier shrink EVA Shrink films provide manufacturers and retailers with the advantage of extending the shelf life of products.All these EVA Shrink films also show a better visual appeal to the product,so as to attract customers.These types of EVA Shrink films mainly affect the shelf life of Chicken and birds, poultry, broiler,cheese, quail, etc.,and create sufficient opportunities for the industry to expand its market trail.

In addition,global consumer concerns about convenience,hygiene and food safety are also increasing,which is affecting the entire packaging industry.

Eva Shrink Film,High Transparent Eva Heat Shrink Film,Eva Pe Shrink Film,Permeable Eva Pe Shrink Film

Tipack Group , https://www.tipackgroup.com