The Benefits of Automation

In the past, manufacturing and industrial companies primarily relied on basic instrumentation to manage processes and produce goods. The focus back then was mainly on precise measurement and reliable control. At that time, material and energy costs were relatively stable throughout the production cycle, and automation was seen merely as a foundational requirement for running operations. Its value was closely tied to the operational processes themselves.

However, as material and energy costs began to fluctuate more unpredictably, companies started to prioritize operational efficiency. They began searching for ways to optimize their production processes to minimize energy and material waste. This shift brought automation to the forefront, where its value extended beyond just supporting operations—it became directly linked to profitability.

Today, automation plays a crucial role in maximizing throughput and minimizing resource consumption. It's now widely adopted across various industrial sectors to ensure safe, efficient, and valuable production outcomes.

Types of Automation Technology

There are several popular methods of business process automation (BPA). Here are three of them:

- Extending an existing IT system: Adding onto an existing automation framework can seem cost-effective initially. However, integrating new elements can be expensive, and training employees to use the updated system can take considerable time and effort.

- Purchasing process-specific BPA software: Specialized software tailored to specific processes can reduce or even eliminate the need for IT assistance during implementation and tool creation. Yet, not every industry can fully utilize all the built-in features, and some sectors might require functionalities that aren't available, making this approach potentially inefficient for many businesses.

- Purchasing adaptive BPA solutions: These solutions combine the advantages of both approaches mentioned above. Companies buy customizable automation software while leveraging their existing infrastructure to develop highly efficient, application-specific solutions.

The Advantages of Automation

Automation brings numerous benefits to various industries and applications. For example, job scheduling software can maximize throughput by automating production batches, which reduces downtime between tasks and minimizes the need for human intervention. Once a schedule is set, automation software executes tasks in a precise sequence, eliminating the possibility of human error. This naturally boosts productivity and reliability, as tasks cannot be overlooked or performed out of order.

Automation brings numerous benefits to various industries and applications. For example, job scheduling software can maximize throughput by automating production batches, which reduces downtime between tasks and minimizes the need for human intervention. Once a schedule is set, automation software executes tasks in a precise sequence, eliminating the possibility of human error. This naturally boosts productivity and reliability, as tasks cannot be overlooked or performed out of order.

Automation also helps minimize energy and material consumption with the same level of precision that ensures seamless scheduling, resulting in significant cost savings and streamlined operations. When recovery systems are automated, the risk of accidental damage to operating systems due to human error is greatly reduced. By enabling environmentally friendly operations and enhancing reliability, automation has proven to be highly effective in preventing failures and maintaining smooth production processes.

Since the economic impact of failure can be quantified, it's straightforward to calculate the potential cost savings from implementing a BPA system. However, because determining the probability of failure is inherently uncertain, industrial companies may not always view failure-event prevention as a clear economic advantage of automation. As a result, throughput, energy, and material consumption remain the primary metrics used to evaluate the overall value of automation systems.

It’s important to note that, similar to any other technology, automation systems can become outdated over time, leading to decreased efficiency and increased costs. Regular updates are essential to maintain consistent ROI, ensure optimal safety and operations, and reduce the environmental footprint.

The Disadvantages of Automation

Despite its advantages, BPA also comes with challenges. Employees often resist change, and a new automation system may be perceived as a complete replacement for manual labor. Even if they embrace the change, training a workforce to effectively implement automation systems can be time-consuming and difficult.

To address these concerns, it's important to reassure employees that automation still requires human oversight and expertise. In fact, their roles may become more specialized post-implementation, potentially leading to higher wages in certain cases. Additionally, the reduced interaction between humans and machines can lead to fewer workplace accidents and less downtime. However, some reduction in staff may still be necessary.

At first glance, the initial costs of adopting BPA might seem counterintuitive, particularly for companies resistant to change. However, the long-term cost and energy savings significantly outweigh any short-term challenges.

Automation Solutions From Sigma Thermal

Sigma Thermal Automation takes pride in offering customized automation solutions tailored to the unique needs of clients across diverse industries and applications. Our skilled engineers, designers, programmers, and fabricators can meet even the most complex project specifications and requirements.

Sigma Thermal Automation takes pride in offering customized automation solutions tailored to the unique needs of clients across diverse industries and applications. Our skilled engineers, designers, programmers, and fabricators can meet even the most complex project specifications and requirements.

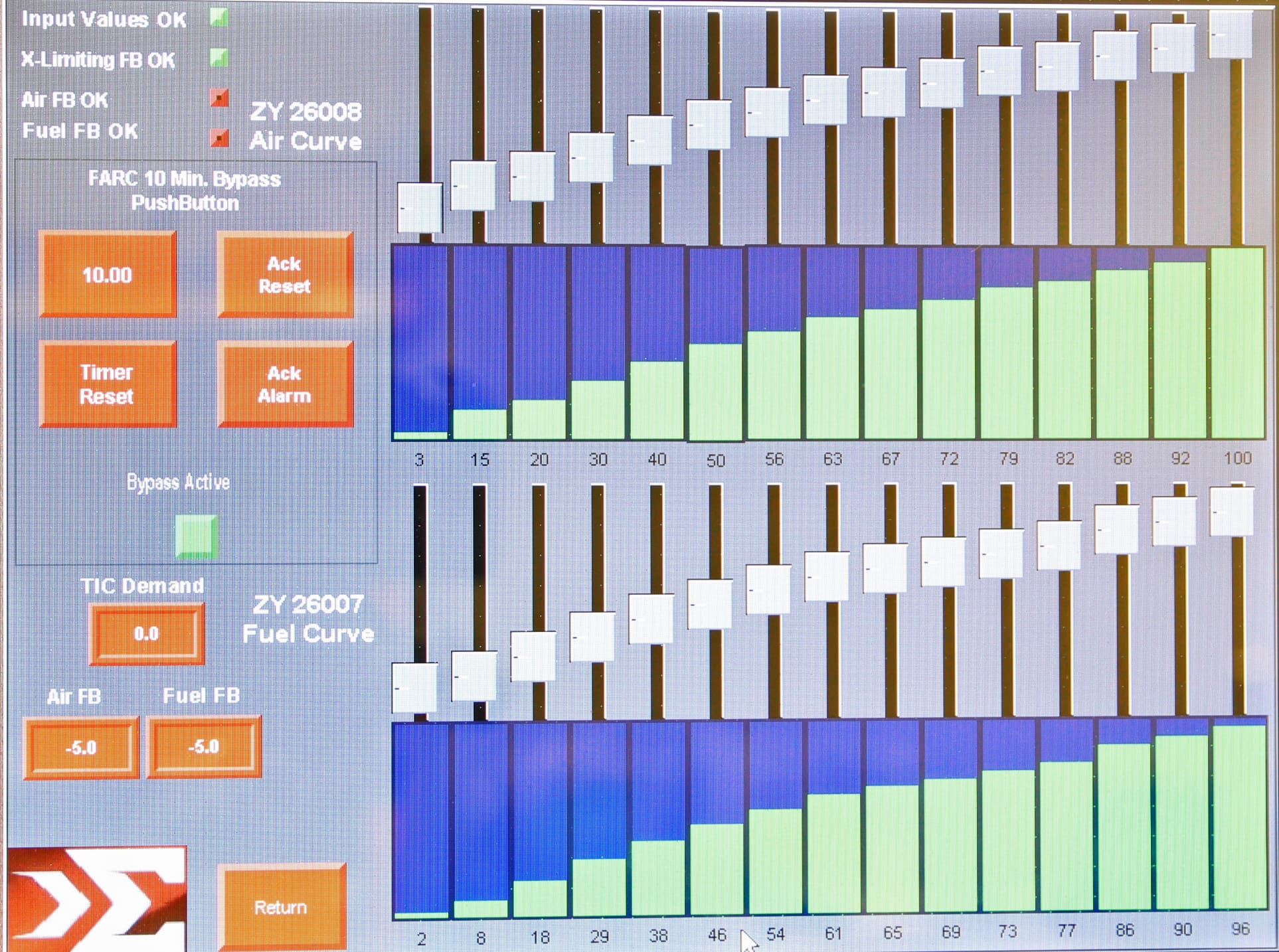

Sigma Thermal provides advanced burner management systems (BMS) and combustion control systems (CCS) to accommodate various customer needs and environmental conditions within the industrial and manufacturing sectors.

We offer comprehensive field services for all new and existing installations, including those from other manufacturers. Our expert technicians can deliver the following services:

- Firmware upgrades and system configuration

- Process tuning, optimization, and validation

- Network configuration and setup

- Programming and troubleshooting

- Commissioning and training

We also adhere to rigorous standards and certifications, including:

- ISO 9001:2015

- U.S. and international certified hardware (CE, UL, FM, CSA, ANSI, ATEX, IEC, etc.)

- U.S. and international compliant system design (CE, FM, NFPA, CSA, IEC, ISA, API, SIL)

For more information about our automation solutions or to discuss how we can assist with your next project, feel free to reach out to our team today.

This article highlights the transformative power of automation in modern industries. While it offers significant benefits such as improved efficiency, cost savings, and enhanced safety, there are challenges to consider, including employee resistance and initial implementation costs. Nevertheless, the long-term advantages of automation far outweigh the hurdles, making it an indispensable tool for businesses aiming to stay competitive in today’s fast-paced world.

Chongqing Dike Technology Industry Co. , Ltd. , https://www.cqdkqc.com

Leave a Reply Cancel reply